Lens Materials

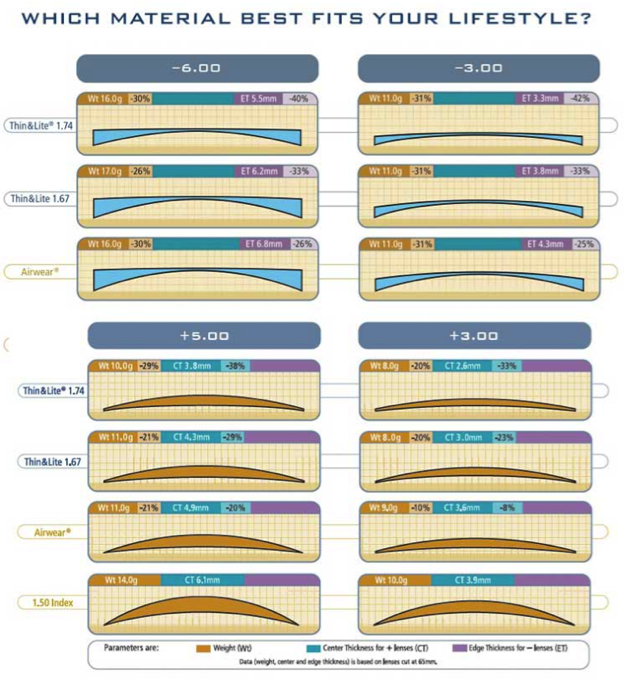

High index lenses 1.6, SuperHigh1.67 and UltraHigh1.74 produce the thinnest and lightest plastic lenses on the market today, up to 50% thinner than standard lens materials.

Airwear and Trivex offer ultra-light, nearly indestructible lens options often used in drill-mount and semi-rimless frames.

Listed below are materials types and how they will benefit your wishes for the lightest lenses possible

| Material | Refractive |

ABBE value |

Specific Gravity |

Benefits |

Transitions |

Crizal |

| Thin&Lite® 1.74 | 1.74 |

33 |

147 |

• Technologically advanced, ultra thin and light weight |

√ |

|

| Thin&Lite 1.67 | 1.67 |

32 |

136 |

• High tensile strength make it great for drill/rimless frames • Great for patients with higher prescriptions • Only 1.67 index available with Varilux designs • 100% UVA and UVB protection |

√ |

√ |

| Thin&Lite 1.60 | 1.60 |

41 |

130 |

• High tensile strength makes it great for drill/rimless frames • Up to 30% thinner and 20% lighter than standard plastic lenses • New and improved material offers all the benefits of high index at an affordable price • 100% UVA and UVB protection |

√ |

√ |

| Airwear® Lenses | 1.59 |

31 |

1.20 |

• 43% lighter and significantly flatter than 1.50 index standard plastic • 10 times more impact resistant than 1.50 index standard plastic • Good choice for sunglass lenses due to its tintability • FDA suggests all children under the age of 16 be prescribed polycarbonate lenses for safety • 100% UVA and UVB protection |

√ |

√ |

| Trivex® Material | 1.53 |

44 |

1.11 |

• High tensile strength makes it great for drill/rimless frames • Low specific gravity, high impact resistance • 100% UVA and UVB protection |

√ |

|

| Plastic | 1.50 |

58 |

1.32 |

• Lightweight compared to glass, works well for low to mid Rx • Good choice for sunglass lenses due to its tintability • Inexpensive material but heavier than others • Less cosmetically appealing |

√ |

√ |